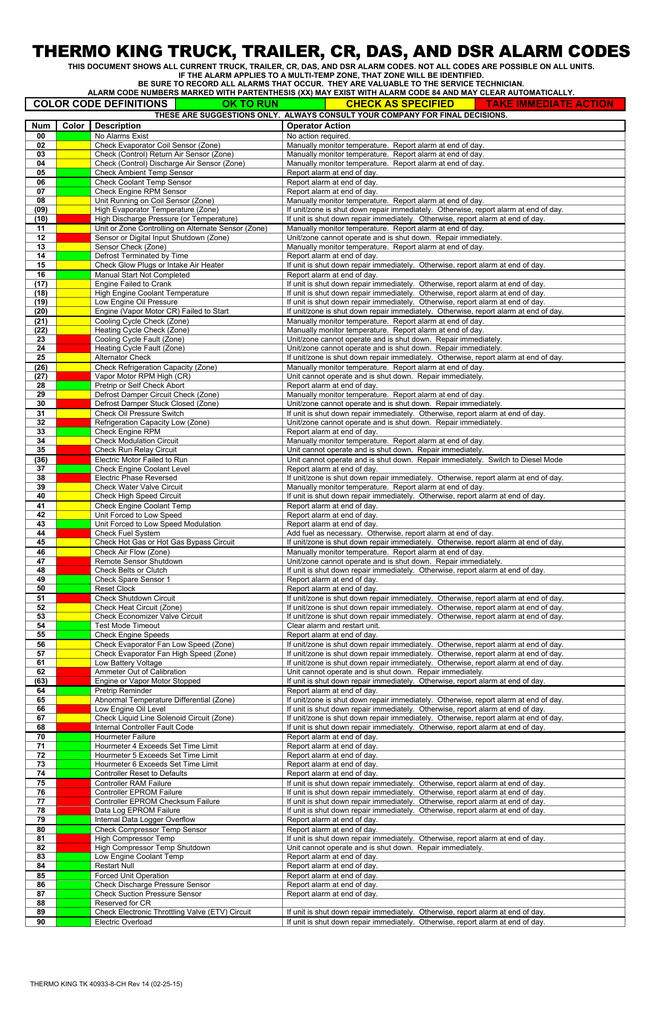

Thermo King Alarm Codes - North America This is a listing of all current truck, trailer, CR, DAS and DSR alarm codes. On multi-temp units, the zone will be identified.

Road Rail Marine Why Thermo King Locate a Dealer Careers Newsroom TracKing Alarm Codes Contact Us Region/Language Road ConnectedSuite™ Telematics Auxiliary Power Units Parts & Accessories for Road Electrification Solutions Road Maintenance Programs Pharma Transport Trailers Trucks & Vans Buses & Shuttles. Thermo King Service & Repair. TKX provides repair and maintenance services, including parts for all types of Thermo King refrigerated units. Including trailer, truck, auxiliary power units. TKX has been Chicago’s transport refrigeration service shop for over 30 years. Trailer Brake Repair & Maintenance Thermo King Tier1- Tier 2 OEM Starter The relay board is essential to transmitting messages in the circuit through an electrical current via the dashboard. New, used and refurbished Thermo King and Carrier Transicold relay boards are available for repair and replacement. Thermo King Alarm Codes For the following units: SB-III 30 SR+, SB-III 30 SR TCI-2, Super II 30 SR+ Thermoguard µP IV, Super II SR TCI-2 Thermoguard µP IV, SB-190, SB-200, SB-300, SB-400, Super II 190 Thermoguard µP VI Controller and SB-210, SB-310, SB-410 with SR-2 Controller. If unit does not re-start and all codes have been cleared.

A guide for troubleshooting alarm codes or fault codes on trailer and truck mounted Thermo King refrigeration units.

This guide lists all the Thermo King alarm codes that could go off on a Thermo King unit. These alarm codes will appear on straight truck refrigeration units and trailer refrigeration units. Just scroll down this page to find out what your alarm code means. If you need help further troubleshooting your Thermo King unit, visit the Mobile Reefer Repair in Sacramento,CA.

Thermo King Alarm Code & Description:

204 issue redundant discharge air sensor

203 issue with redundant return air sensor

137 issue with damper motor heater output

136 issue with spare digital outputs

135 issue with spare digital inputs

134 controller power on hours

133 total unit run time maint reminder # 2

132 total unit run time maint reminder # 1

131 engine run time maint reminder # 2

130 engine run time maint reminder # 1

129 engine run time maint reminder # 2

128 engine run time maint reminder # 1

127 setpoint not entered

126 issue with back pressure regulator

125 issue with tank level sensor

124 issue with evap coil outlet temp sensor

123 issue with evap coil inlet temp sensor

122 issue with diesel/electric circuit

121 issue with pmw liquid injection circuit

120 issue with alternator excite circuit

119 reserved for cr

118 auto switch from electric to diesel

117 auto switch from diesel to electric

116 issue with high pressure cut in switch

115 issue with high pressure cut out switch

114 multiple alarms- can not run

113 issue with elerctric heat circuit

112 issue with remote fans

111 unit not configured correctly

110 issue with suction line sol circuit

109 issue with high discharge pressure sensor

108 door open timeout

107 issue with condeensor inlet sol circuit

106 issue with purge valve circuit

105 issue with receiver tank press sol circuit

104 issue with remote fan speed

103 low heater fuel level

102 low evaporator coil temperature

101 controlling on evap coil outlet temp

100 heater fan failure

99 high compressor pressure ratio

98 issue with fuel level sensor

97 failed remote return air sensor

96 low fuel level

95 issue with loader # 2 circuit

94 issue with loader # 1 circuit

93 low compressor suction pressure

92 sensor grades not set

91 issue with electric ready input

90 electric overload

89 issue with electronic throttling valve circuit

88 reserved for cr

87 issue with suction pressure sensor

86 issue with discharge pressure sensor

85 forced unit operation

84 restart null

83 low engine coolant temp

82 high compressor temp shutdown

81 high compressor temp

80 issue with compressor temp sensor

79 internal data logger overflow

78 data log eprom failure

77 controller eprom check sum faliure

76 controller eprom failure

75 controller ram failure

74 controlleer reset to defaults

73 hourmeter 6 exceeds set time limit

72 hourmeter exceeeds set time limit

71 hourmeter 4 exceeds set time limit

70 hourmeter failure

69 issue with remagnetization circuit

68 internal controller fault code

67 issue with liquid line solenoid circuit

66 low engine oil level

65 abnormol temperature differential

64 pretrip reminder

63 engine or vapor motor stopped

62 ammeter out calibration

61 low battery voltage

60 issue with boost circuit

59 issue with condenser fan high speed

58 issue with condenser fan low speed

57 issue with evaportor fan high speed

56 issue with evaportor fan low speed

55 issue with engine speeds

54 test mode timeout

53 issue with economizer valve circuit

52 issue with heat circuit

51 issue with shutdown circuit

50 reset clock

49 reserved for cr

48 issue with belts or clutch

47 remote sensor shutdown

46 issue with air flow

45 issue with hot gas or hot gas bypass circuit

44 issue with fuel syatem

43 unit forced to low speed modulation

42 unit forced to low speed

41 issue with engine coolant temp

40 issue with high speed circuit

39 issue with water valve circuit

38 electric phase reversed

37 issue with engine coolant level

36 electric motor failed to run

35 issue with run relay circuit

34 issue with modulation circuit

33 issue with engine rpm

32 refrigeration capacity low

31 issue with oil pressure switch

29 defrost damper circuit issue with

28 pretip or self check abort

27 vapor motor rpm high (cr)

26 issue with refrigeration capacity

25 alternator check

24 heating cycle fault

23 cooling cycle fault

22 heating cycle fault

21 cooling cycle check

20 engine ( vapor motor cr) failed to start

19 low engine oil pressure

18 high engine coolant temperature

17 engine failed to crank

16 manual start not completed

15 issue with glow plugs or intake air heater

14 defrosat terminate by time

13 sensor check

12 sensor or digtal input shutdown

11 unit controlling on alternate sensor

10 high discharge pressure (or temp)

09 high evaporator temperature

08 unit running in coil sensor

07 issue with engine rpm sensor

06 issue with coolant temp sensor

05 issue with amibent temp sensor

04 issue with discharge air sensor

03 issue with return air sensor

02 issue with evaporator coil sensor

01 microprocessor power up reset

00 no alarms exist

Information for this article was sourced from Transport Refrigeration website.

- TKX Transport Refrigeration has over 60 years experience in Thermo King repair and Carrier Transicold repair for Refrigerated Trailer, Truck, Van and A.P.U. Units

- TKX Offers 24 hour a day Emergency Service (extra fees may apply)

- Thermo King Alarm Codes and Carrier Alarm Codes

Transport Refrigeration Repair & Service

TKX Transport Refrigeration has over 60 years of experience servicing both Thermo King and Carrier refrigerated trailer, truck, van and A.P.U. units. We have an excellent inventory of OEM parts to minimize downtime and get your refrigeration units serviced and back on the road. In fact, emergency repair is not only our specialty, but our pride and joy. Our experienced refrigeration mechanics understand the value of your time – getting your unit up and running in the absolute shortest time possible is our #1 priority, whether you are in the shop or on the road. We know that if a load of fruits, vegetables or meats isn’t being refrigerated on the road due to some mechanical mishap, there is no time to waste. We also understand the sooner you are able to get going again, the more likely you are to avoid insurance damages.

Our accuracy and speed are what set us apart from the rest, and TKX specializes in being Chicago’s most reliable and speedy cold transport repair mechanics. In the shop, we have numerous technicians on hand to do the job right, and in an emergency, we come to you and make sure you don’t lose any time, money or cargo due to refrigeration failure.

Trailer Washout Service

Trailer washouts refer to having the inside of a semi-truck trailer cleaned. This isn’t the same service as a trailer wash or truck wash, which refers to having the outside of a truck or trailer cleaned. Trailer washouts are normally recommended at least once a week or more often as needed. But as the country is dealing with increased levels of concern over potential opportunities for the spread of contaminates in the wake of the COVID-19, recent changes now require washouts to be done after every load or haul. These involve thoroughly cleaning the inside areas of a semi-truck trailer with hot water to prevent contamination and lower the risk of other problems.

Find out more about our Trailer Washout Service in Chicago, IL and Book your washout today!

Preventative Maintenance & Inspection

Every truck & trailer, but especially the refrigerated auto unit, needs regular maintenance and inspection. For Thermo King and Carrier refrigeration units, TKX Transport has all the tools and expertise necessary to ensure proper servicing to last your entire journey. TKX specializes in repairing refrigeration units using a large inventory of OEM parts, and we also inspect the truck and trailer to ensure all pieces of machinery operate smoothly together.

For regular maintenance and inspection, we overlook no part of the job because we want to get you out on the road with confidence and ease. Regular maintenance of refrigerated trailers is recommended at 1,500 hours, 3,000 hours and 4,500 hours (annually). Our experienced refrigeration mechanics check the refrigeration unit for adequate cooling, proper oil, working belts and everything else required for reliable mobile refrigeration. We take pride in visually inspecting the unit, cleaning any oil spills, clearing debris, making sure air flow is unobstructed, rotating fan motors and blades, tightening any electrical connections and more. We have six decades of experience in this industry, so we operate with the big picture in mind without sacrificing attention to detail.

Here’s our Refrigeration Maintenance & Inspection Checklist

Trailer Brake Repair

For any vehicle, maintaining functioning brakes is one of the most essential safety measures any driver can take, but it is especially important for professional truck drivers hauling tons of cargo over long distances. Depending on load and terrain, most heavy duty trucks have brake linings that need to be replaced once every 2 years. This is not a repair you can afford to miss! There is nothing more dangerous than a heavily loaded truck with failing brakes, but luckily, TKX Transport has the maintenance skills you can trust to keep your brakes in good shape.

With over 60 years of experience, we will check your brake lining regularly and help you plan to replace parts ahead of time, minimizing any risk for damages. We will also assess any safety hazards beyond regular wear and tear. Depending on the types of terrain driven, different trucks need different brake linings, and one of the best ways to damage your vehicle is to select the wrong material for this job. For example, driving through forests, mountains or cities with a lot of starting and stopping would require premium semi-grade metallic that can withstand a lot of friction. Our expert mechanics will take all relevant factors into account to find out exactly what you need to have the best working brakes possible.

Thermo King Code 04

No one will be on the road with faulty brakes; we make sure of it.

Trailer Lighting Repair & Service

As a commercial driver, even if the rest of your truck is running smoothly, any sort of light failure makes you a hazard on the road and also liable for hefty fines. In order to prevent any run-ins with local law enforcement or worse, an accident due to poor visibility, let TKX provide regular circuitry check ups for your electrical lighting system.

We will use specialized tools to check the health of the wires and the ability for electricity to be conducted from source to bulb, as well as replace any faltering light bulbs, strengthen any wire connections, replace any broken wires, and clean away or replace any rusted parts. All of Chicago would tell you, with us you can be sure that trailer lighting is not likely to be an unexpected problem on dark nights. And if any aspect of truck lighting gets tangled along the way, TKX is here to illuminate the most accurate and reliable repair techniques.

Insurance Maintenance Inspection

Commercial truck drivers usually carry some sort of insurance plan for the driver, the vehicle and the cargo. Making sure that all the requirements of the insurance plan are met is key to protecting against any possible damages. Freight carrying insurance plans require that any refrigerated truck unit be regularly inspected, serviced, maintained and repaired on a schedule determined by the maker of the trailer.

TKX is familiar with major insurance carriers and their requirements, as well as the schedules set by the makers of trailers and refrigeration units, so we can get your truck and cooling unit serviced and up to par with no hassle. Don’t take the chance of slacking on insurance maintenance; let TKX Transport complete all the required maintenance for you to stay 100% compliant.

Insurance Claim Work

If you are a commercial driver who has been in an auto accident, has gotten a traffic violation or has been cited for fix-it work, you will need to have the vehicle inspected and a claim made to your insurance company. Here in Chicago, TKX Transport Refrigeration will take care of your insurance claims and do the required investigation of the mobile cold storage vehicle to submit to your insurance carrier. No one likes getting caught up in red tape, but you can trust TKX to handle and submit any insurance claim that requires repair and investigation of any refrigerated auto unit.

DOT Certified Inspections

In order to ensure safety on the road, the U.S. Department of Transportation requires that every commercial truck and large bus must pass an annual DOT inspection. TKX is a certified and approved DOT inspector, and with 60 years in business, our DOT inspection process has been nailed down. We follow all DOT guidelines and inspect, repair and service the refrigerated truck and trailer as it needs. In order to pass the DOT inspection, you need accurate records, astute observations, quality repair skills and extensive experience, all of which TKX Transport is happy to provide.

Our customer service is excellent and we will make sure we do everything possible to pass your refrigerated truck or trailer. Don’t get stopped at any Chicago tollbooths for a spontaneous DOT inspection without possessing the utmost confidence in your vehicle that comes from regular TKX maintenance and a DOT passing grade.

Thermo King & Carrier Parts Supply (OEM, Reconditioned & Used)

Thermo King and Carrier account for roughly 90% of all mobile refrigerated systems, so it is vital that any refrigeration repair company have an expansive store of both knowledge and parts for these two major companies. TKX Transport Refrigeration is proud to satisfy both; we keep a vast supply of Thermo King and Carrier parts on company property so we are always prepared with the right equipment, and our experienced team of technicians is standing at the ready to implement their many years of experience.

Thermo King Repair Shops

We won’t keep you waiting by shopping around; we’ve already got everything we’d need to get the job done in no time. Offering an array of new OEM (original equipment from manufacturer) parts, reconditioned parts and gently used parts, we also strive to give you the best deal possible from a wide variety of Thermo King and Carrier auto parts. TKX Transport is your one stop shop for mobile cold storage parts replacement.